OLIVE OIL

production process

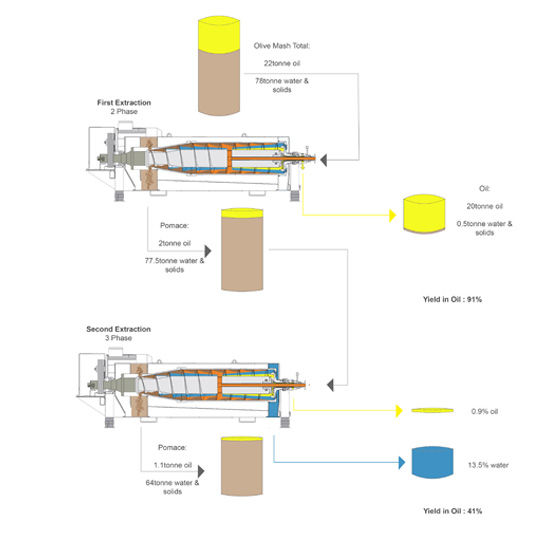

The modern method of Olive Oil extraction uses an industrial decanter to separate all the phases by centrifugation. In this method the olives are crushed to a fine paste. This can be done by a hammer crusher, disc crusher, de-pitting machine or knife crusher. This paste is then mixed or stirred for 30 to 40 minutes to allow the small olive droplets to combine into larger droplets. The aromas are created in these two steps through the action of fruit enzymes.

Afterwards the paste is pumped into an industrial decanter where the phases will be separated. Water is added to facilitate the extraction process with the paste. The decanter is a large capacity horizontal centrifuge rotating at approximately 3000 rpm. The high centrifugal force created allows the oil and the water to be easily separated because of their different densities. Inside the decanter's rotating conical drum there is a coil that rotates a slower, pushing the solid materials out of the system.

The separated oil and vegetation water are then rerun through a vertical centrifuge, working at nearly 6000 rpm that will separate any other left over small quantities of oil from the water.

Yield of 10.7l produced per day = 42x250ml btl